Introduction

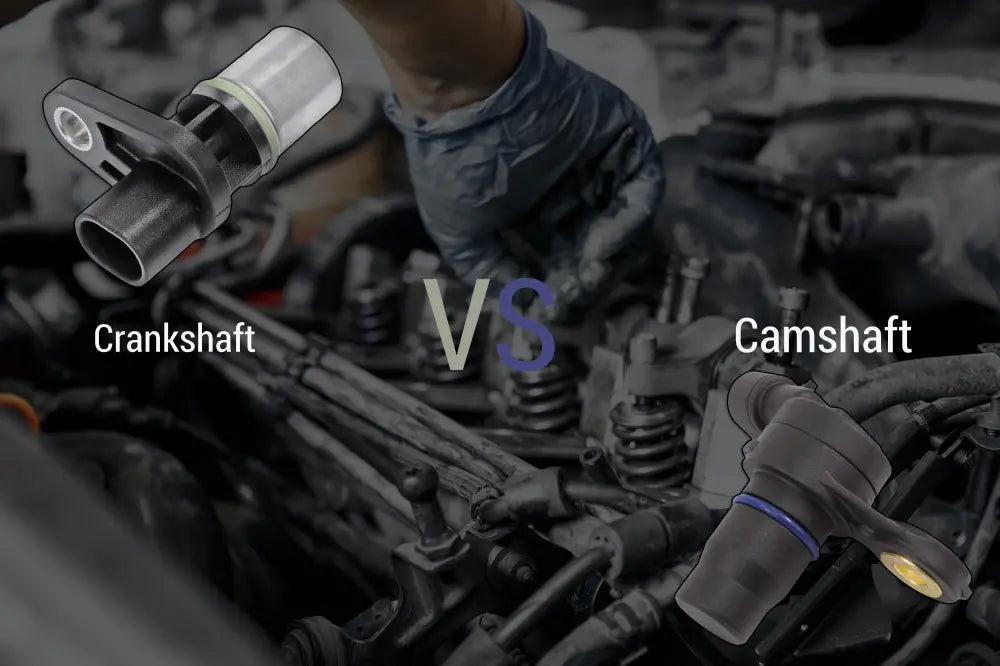

If you’ve ever popped the hood of your car and wondered why there are so many different sensors monitoring your engine, you’re not alone. Two of the most important — yet often confused — are the crankshaft position sensor and the camshaft position sensor.

Both play a crucial role in engine timing, fuel delivery, and overall performance. But here’s the twist: while they work together, they are not interchangeable. Knowing the difference can save you time, money, and frustration when diagnosing issues.

In this article, we’ll break down:

-

What each sensor does

-

How they differ in design, location, and function

-

Common failure symptoms

-

How to test and replace them

-

Whether you can still drive if one fails (spoiler: not recommended)

1. What Is a Crankshaft Position Sensor?

The crankshaft position sensor (CKP) is like your engine’s “heartbeat monitor.” It tracks the position and rotational speed of the crankshaft, which directly affects ignition timing and fuel injection.

Without an accurate crankshaft signal, your engine control unit (ECU) is basically operating blind. The ECU uses this data to:

-

Determine when to fire the spark plugs

-

Control fuel injection timing

-

Monitor engine RPM

Typical Locations

-

Near the crankshaft pulley

-

On the engine block, close to the flywheel or harmonic balancer

Common Designs

-

Magnetic inductive sensor – uses a toothed wheel to create a signal

-

Hall-effect sensor – produces a digital signal

2. What Is a Camshaft Position Sensor?

The camshaft position sensor (CMP) monitors the position of the camshaft(s) relative to the crankshaft. This is essential for sequential fuel injection and variable valve timing (VVT) systems.

If the crankshaft sensor is the heartbeat monitor, think of the camshaft sensor as the “breathing monitor.” It ensures that intake and exhaust valves open and close at precisely the right time.

Typical Locations

-

On the cylinder head, near the camshaft gear

-

Inside the timing cover

Common Designs

-

Hall-effect

-

Magnetic

3. Crankshaft vs. Camshaft Sensor: Key Differences

| Feature | Crankshaft Sensor (CKP) | Camshaft Sensor (CMP) |

|---|---|---|

| Purpose | Monitors crankshaft position and RPM | Monitors camshaft position relative to crankshaft |

| Impact | Ignition timing, fuel injection | Sequential fuel injection, VVT |

| Location | Near crankshaft pulley or flywheel | Near camshaft gear or cylinder head |

| Engine Startup | Without CKP, engine will not start | Without CMP, engine may start but run poorly |

| Signal Type | Often higher resolution | Often lower resolution |

| Cost | Typically $30–$150 | Typically $30–$150 |

4. How They Work Together

The CKP tells the ECU the crankshaft’s exact position, while the CMP fine-tunes the timing by indicating which cylinder is on the compression stroke.

Example scenario:

-

CKP says: “The crankshaft is at 10 degrees before top dead center.”

-

CMP says: “Cylinder #1 is ready for ignition.”

This teamwork ensures optimal power, efficiency, and reduced emissions.

5. Symptoms of a Bad Crankshaft Sensor

-

Engine won’t start

-

Stalling at idle or while driving

-

Misfires or rough running

-

Check Engine Light (CEL) with codes like P0335

-

Reduced fuel economy

6. Symptoms of a Bad Camshaft Sensor

-

Hard starting or long crank time

-

Loss of power

-

Poor acceleration

-

Check Engine Light (CEL) with codes like P0340

-

Shifting issues (in some automatic transmissions)

7. Can You Drive with a Bad Crankshaft or Camshaft Sensor?

-

Bad CKP: Almost always a no-go. The engine may not start at all.

-

Bad CMP: Sometimes yes, but you’ll experience poor performance and risk long-term damage.

Driving with either sensor malfunctioning is risky — you could be stranded or damage other engine components.

8. Testing and Diagnosing

To confirm which sensor is failing:

Step 1: Use an OBD2 Scanner

Plug in a scanner like the CGSULIT SC880 or SC530. Look for codes:

-

CKP: P0335, P0336

-

CMP: P0340, P0341

Step 2: Visual Inspection

Check for:

-

Damaged wiring

-

Corrosion at connectors

-

Metal debris on magnetic tips

Step 3: Measure Signal Output

With a multimeter or oscilloscope, check resistance or voltage according to your vehicle’s service manual.

9. Replacement Cost and DIY Tips

-

Parts cost: $30–$150 per sensor

-

Labor: $75–$200, depending on location

-

Many crankshaft sensors are harder to reach than camshaft sensors

If you’re DIY-ing:

-

Disconnect battery

-

Remove any obstructing parts (timing covers, air intake, etc.)

-

Replace sensor and reconnect wiring

-

Clear codes with your OBD2 scanner

10. Preventive Maintenance Tips

-

Keep oil clean — dirty oil can damage camshaft sensors

-

Inspect wiring regularly

-

Avoid washing engine bay aggressively with high-pressure water

11. FAQ

Q: Can I replace a camshaft sensor with a crankshaft sensor?

A: No. They have different designs, mounting points, and functions.

Q: Which fails more often?

A: Camshaft sensors often fail more due to heat and oil exposure, but both can fail with age.

Q: Will a bad camshaft sensor cause a no-start?

A: Sometimes. The engine may crank but take longer to start or misfire badly.

Q: Should I replace both sensors at the same time?

A: If one fails and your car is high mileage, replacing both can prevent future breakdowns.

Conclusion

While the crankshaft position sensor and camshaft position sensor may seem similar, they serve different — yet complementary — roles in keeping your engine running smoothly.

Understanding their differences helps you make smarter repair decisions, especially when that dreaded Check Engine Light comes on. Whether you’re a DIY mechanic or heading to a shop, accurate diagnosis is key.

If you want to diagnose these issues yourself, a quality OBD2 scanner can save you hours of guesswork and hundreds of dollars in unnecessary repairs.

Related Article

How to Relearn Crankshaft Sensor Position with an OBD2 Scanner?

Crankshaft Maintenance: Tips for Longevity

5 Common Symptoms of a Bad Crankshaft Position Sensor

The Best OBD2 Scanners with Crankshaft Relearn Function