Your car sounds fine one morning. The next, it idles like it’s coughing, stalls at a stoplight, or hesitates when you press the gas. Suddenly you’re staring at a dashboard that feels less like a control panel and more like a mystery to solve. One of the most common, and surprisingly consequential, components behind those symptoms is the throttle body.

This article explains, in clear terms, what a throttle body does, how it fits into modern engine management, and the most reliable signs that it may be failing or clogged. I’ll also cover why the throttle body matters for emissions, performance, and safety — and when it’s time to involve a professional. No step-by-step cleaning guide here; instead you’ll get the knowledge to diagnose, understand, and decide on the next move with confidence.

Quick overview: why the throttle body matters

The throttle body controls the flow of air into the engine. That sounds simple, but air flow is one half of the combustion equation — fuel being the other. Small changes in how air enters the engine can ripple into big changes in performance and efficiency. Modern cars rely on precise electronic control. When that control loses accuracy, the result is often a visible or audible symptom: rough idle, hesitation, stalling, poor fuel economy, or even limp-home modes.

Put bluntly: ignoring throttle body problems rarely ends well. A small issue today can cascade into a bigger one later.

What exactly is a throttle body?

At its core, the throttle body is a valve — usually a rotating disc called a throttle plate or “butterfly” — installed in the intake tract between the air filter and the intake manifold. It meters incoming air to match the driver’s demand at the accelerator pedal.

On older cars, the throttle was mechanically linked to the gas pedal with a cable. Push the pedal, the cable pulls, the throttle opens. Simple, mechanical, direct.

Today’s cars mostly use electronic throttle control (ETC), often referred to as drive-by-wire. In these systems, you press the accelerator. Sensors measure pedal position and send a signal to the engine control unit (ECU). The ECU decides how much to open the throttle plate and instructs an electric motor to move it. There’s no physical cable. That opens the door to more precise control, better fuel economy, lower emissions, and integrated safety features — but it also adds electronics that can fail.

Key components you’ll hear about:

-

Throttle plate (butterfly valve): the physical disk that opens and closes.

-

Throttle position sensor (TPS): reports the plate’s position back to the ECU.

-

Idle control (IAC) or an integrated idle function: manages air at idle in many designs (sometimes replaced by ECU-managed throttle adjustments).

-

Motor/actuator: in drive-by-wire systems, this physically moves the throttle plate.

How the throttle body works in everyday driving

Think of the throttle body as the engine’s breath regulator. When you ask for more power — more throttle — the plate opens to allow more air in. The ECU senses that and increases fuel accordingly so the air-fuel mix stays balanced for combustion. It’s a continuous feedback loop:

-

Driver presses the accelerator (pedal).

-

Pedal position sensors send a signal to the ECU.

-

ECU calculates required throttle opening and injector pulse width (fuel).

-

ECU commands the throttle motor/actuator to move the plate.

-

TPS reports actual plate position back to the ECU for confirmation.

-

The cycle repeats hundreds of times per second.

Modern ECUs also use knock sensors, oxygen sensors (O2), mass air flow (MAF), and manifold absolute pressure (MAP) sensors to fine-tune this process. The throttle body is the gate; the rest of the sensors tell the brain (ECU) how to set that gate for optimal combustion.

Why throttle body problems happen

There are two broad causes of throttle body problems:

-

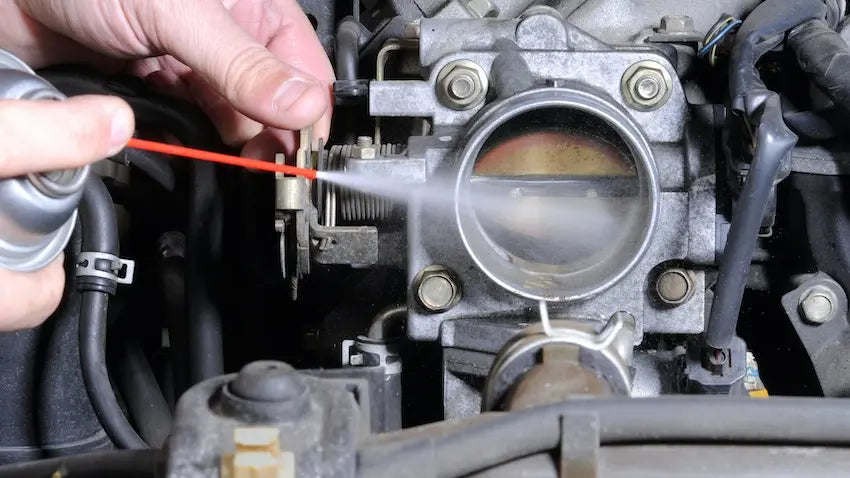

Contamination and carbon buildup. Over time, oil vapors from the crankcase ventilation system, combined with fuel residues and road dirt, form deposits around the throttle plate and inside the throttle housing. This is especially common on direct-injection engines and cars with extended oil change intervals. The result is restricted airflow and a throttle plate that may not seat cleanly.

-

Electronic or mechanical failure. In drive-by-wire systems, the motor, sensor, or wiring can fail. The throttle position sensor may give inaccurate readings. The actuator may move sluggishly. Wiring can be corroded or chafed. Mechanical linkages (in older cars) can stick or break.

Both contamination and electronic issues can produce similar driving symptoms — which is why a clear diagnosis matters.

Common symptoms of a bad or failing throttle body

Below are the most reliable indicators that your throttle body needs attention. Each item includes the typical cause and what it may mean for your next step.

1. Rough or unstable idle

What you’ll experience: The engine shakes or vibrates while idling, RPMs fluctuate, or the car feels uneven when stopped.

Why it happens: Carbon buildup around the throttle plate disrupts the steady flow of air needed to maintain a stable idle. In electronic systems, incorrect throttle position input or poor motor response forces the ECU to hunt for a steady idle, creating RPM swings.

What it signals: Early-stage contamination or sensor/actuator inconsistency.

2. Stalling at low speeds or when coming to a stop

What you’ll experience: The engine dies as you stop at a light or pull into a parking spot.

Why it happens: If the throttle cannot provide the tiny controlled airflow needed at idle, or if the ECU is receiving irregular position signals, the engine cannot sustain combustion at low RPMs.

What it signals: A problem that can be dangerous in traffic — prioritize diagnosis.

3. Hesitation, surging, or poor acceleration

What you’ll experience: You press the accelerator, but the car hesitates or surges before responding, or it feels inconsistent when accelerating.

Why it happens: The throttle plate may stick, or the TPS may report an inaccurate opening. The ECU can’t maintain a smooth relationship between pedal input and throttle response.

What it signals: Likely either mechanical restriction or electronic mismatch.

4. Check Engine Light with related codes

What you’ll experience: CEL illuminates. A diagnostic scan reveals codes such as P0121, P2101, P2119, or other throttle/drive-by-wire related codes.

Why it happens: The ECU monitors the throttle circuit and throws codes when expected signals are absent, out of range, or inconsistent.

What it signals: Electronic or sensor fault; reading live data helps determine whether it’s wiring, sensor, or the throttle body itself.

5. Reduced fuel economy

What you’ll experience: You’re filling the tank more often than usual. MPG drops without obvious changes in driving style.

Why it happens: If the ECU compensates for inaccurate airflow readings by adding more fuel (or running conservative timing maps), fuel economy suffers.

What it signals: Chronic inefficiency that warrants a timely fix.

6. Unresponsive or limp-mode behavior

What you’ll experience: The vehicle enters a reduced-power state (limp mode) to protect the engine. Acceleration is intentionally limited.

Why it happens: The ECU detects critical faults in the throttle control circuit and cuts power to prevent unsafe conditions.

What it signals: Serious electronic or safety-related failure that usually requires professional attention.

7. Surging or high idle after throttle service (contextual)

What you’ll experience: Following certain services (like intake cleaning or sensor replacement), the idle is unusually high or variable.

Why it happens: Many modern cars require a learning or relearn procedure after throttle service. Without that, the ECU’s learned idle parameters may be out of sync.

What it signals: Not necessarily a failure — sometimes a need for recalibration.

Dirty throttle body vs. failing throttle body — how to tell the difference

Symptom overlap makes this distinction tricky without a proper scan. Generally:

-

Dirty throttle body: Symptoms usually develop gradually, are intermittent, and often respond to cleaning or reverting after a short period. Rough idle, slight hesitation, and slightly reduced fuel economy are typical early signs.

-

Failing throttle body (electronic/mechanical): Symptoms can be more abrupt and may include CEL with specific fault codes, limp mode, or erratic throttle response that does not improve after cleaning or resets.

When in doubt, a diagnostic scan capturing live data (throttle position, commanded position, and error counts) helps differentiate between contamination and an electronic fault.

Diagnostic approach — what a technician will check

Here’s a high-level overview of the diagnostic steps a competent technician will follow. This is not a DIY how-to; it’s intended to help you understand the logic behind the diagnosis and to communicate more effectively with a shop.

-

Read trouble codes and freeze-frame data. This tells the technician when the fault occurred and under what conditions (load, RPM, temperature).

-

Visual inspection. Check connectors, wiring harness routing, and signs of heat or oil contamination. Look for cracked insulation or signs of rodent damage.

-

Compare commanded vs. actual throttle position. With a scan tool, technicians compare the ECU’s commanded throttle opening to the actual position reported by the TPS. Large discrepancies point to a sensor or actuation problem.

-

Check for mechanical restriction. If the throttle plate is physically sluggish (binding on its shaft) or carboned over, that should be evident with intake removal or with specialized inspection tools.

-

Verify related sensors. Issues with MAF, MAP, crank/cam sensors, or fuel system problems can create symptoms mirroring throttle issues; technicians rule these out.

-

Perform functional tests. Using a manufacturer-level scan tool, technicians can command the throttle and observe behavior, sometimes comparing it to known-good parameters.

-

Review ECU relearn requirements. If the throttle has been serviced or replaced, the technician checks whether a relearn or calibration routine is needed.

This systematic approach protects you from unnecessary parts replacement and ensures the right fix.

Safety and emissions implications

Throttle body faults are not just an annoyance — they can affect safety and compliance.

Safety: Stalling in traffic or unexpected loss of power can create hazardous situations. A vehicle that hesitates while merging or on a hill is at risk in heavy traffic.

Emissions: Incorrect air-fuel ratios and timing adjustments to compensate for throttle anomalies can increase NOx and hydrocarbon emissions. Persistent faults often lead to failed emissions tests or warnings during annual inspections.

Hence, prompt diagnosis matters for both safety and legal compliance.

Cost considerations and what to expect from a repair shop

If your throttle body requires replacement or a deep electronic fix, expect a range of costs depending on vehicle complexity:

-

Diagnostic fee: Most shops will charge for diagnosis (commonly $80–$150), which is offset if you proceed with repairs there.

-

Parts: A replacement throttle body (OEM) can range widely — typically from around $150 on smaller cars to $500+ on higher-end models or OEM-specific units. Some throttle bodies include the throttle motor and TPS in one assembly; others are modular.

-

Labor: Labor costs depend on accessibility. On transverse-mounted engines or vehicles with complex intake assemblies, labor can be significant (sometimes 1–3 hours). Labor rates vary by region and shop.

-

Total job: A typical total can range from roughly $300–$900 depending on parts and labor.

Note: in many cases, a professional will first attempt to resolve contamination or perform calibrations before recommending a full replacement.

Practical advice for owners (what you can and should do)

-

Don’t ignore the symptoms. Rough idles, hesitation, or a CEL that mentions throttle/TP sensors deserve prompt attention.

-

Record the circumstances. When the problem occurs (cold start, under load, while idling) — this makes diagnosis faster and less expensive.

-

Ask for live-data evidence. Reputable shops will show you live scan data (commanded vs actual throttle) to justify repairs; ask to see it.

-

Inquire about OEM vs aftermarket parts. For drive-by-wire systems, using OEM or a quality OEM-equivalent part is often the safest choice. Cheap knockoffs can create recurring issues.

-

Keep maintenance records. If your intake or PCV system has been serviced recently, this can be useful information for the technician.

Frequently asked questions (quick answers)

Q: Can a bad throttle body cause my car to stall?

A: Yes. A throttle that cannot supply stable idle airflow or an ECU that receives faulty position data can cause stalling, particularly at low speeds.

Q: Will the check engine light always come on?

A: Not always. Early-stage contamination may not trigger a code immediately. But electronic faults usually generate specific throttle-related codes.

Q: Are throttle bodies a routine wear item?

A: No — they’re not designed to fail quickly. Many last decades. Still, heat, deposits, and electronics mean replacement sometimes becomes necessary, especially at higher mileages.

Q: Is it dangerous to drive with a faulty throttle body?

A: Short trips at low speed may be tolerable, but driving under load (towing, highway merging) with a compromised throttle control can be risky. If limp mode or heavy knocking is present, stop driving and get it checked.

Conclusion — pay attention to the small things

The throttle body is small in size but large in importance. It sits at the intersection of driver demand and engine response, and modern cars depend on it to balance performance, economy, and emissions. Symptoms that begin small — a slight roughness at idle, a hesitant throttle — are the engine’s way of telling you something needs attention. Listen to those signals.

If you notice persistent symptoms, get a proper diagnosis. That saves money, time, and stress down the road. And if you want help understanding a specific fault code or reading scan results, tell your mechanic to capture live throttle position data and compare it with commanded values — that’s the most reliable way to find the true cause.

Related Article

How to Relearn Throttle Body with the OBD2 Scanner?

P0121 Explained: The Common Symptoms and Causes You Need to Know